Lithium-ion Capacitors Can Help You Provide High-Quality Power in Tough Environments

If you’ve worked on distributed power solutions using rechargeable batteries or electric double-layer supercapacitors (EDLCs), you’re familiar with their limitations. Batteries have tradeoffs related to environmental performance, system size, and safety, which increase costs and decrease their effectiveness. EDLCs can address some of these issues, but they just don’t have the needed energy capacity for many applications.

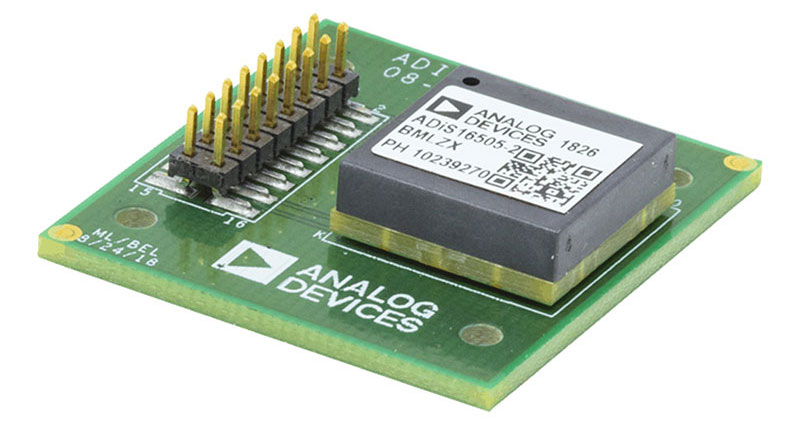

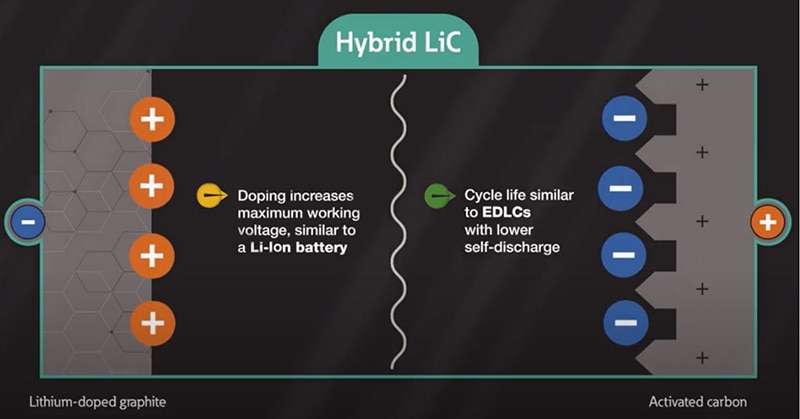

To address these limitations, you can turn to lithium-ion capacitors (LICs), also called hybrid supercapacitors. If you’re not yet familiar with them, LICs are asymmetric devices blending two different technologies; the cathode is like a supercapacitor, and the anode is similar to a Li-ion battery (Figure 1). Their asymmetric structure makes LICs well suited for power quality applications that can benefit from high energy densities, high power densities, environmental ruggedness, and durability.

Figure 1: LICs blend two different technologies in an asymmetric structure; the anode is similar to a Li-ion battery, and the cathode is like a supercapacitor. (Image source: Eaton)

Figure 1: LICs blend two different technologies in an asymmetric structure; the anode is similar to a Li-ion battery, and the cathode is like a supercapacitor. (Image source: Eaton)

LICs can provide backup power and protection from voltage sags during peak power draws. In industrial systems such as chemical plants and semiconductor manufacturing, even a brief disruption of power quality can result in costly downtime. Brownouts and power outages can disrupt the operation of cache memories, RAID systems, and storage servers in data centers.

Let’s consider three examples of LICs suitable for use in power quality protection applications on the edge, one each from Eaton, Taiyo Yuden, and Tecate Group, and then close with a brief look at some design considerations you need to be aware of when using LICs.

LICs rated for operation down to -25°C

Many LICs have an operating temperature range of -15 to +70 °C, but if your application needs to work in a colder environment, Eaton offers the HSL1016-3R8306-R, a 30 farad (F) LIC that is specified for operation down to -25°C (Figure 2). This LIC is rated for more than 250,000 charging cycles at 20°C ambient temperature and has a maintenance-free service life of up to 20 years. It delivers up to eight times the energy density of standard supercapacitors.

Figure 2: The HSL1016-3R8306-R is a 30 F LIC that operates down to -25°C and is rated for more than 250,000 charging cycles at 20°C ambient. (Image source: Eaton)

Figure 2: The HSL1016-3R8306-R is a 30 F LIC that operates down to -25°C and is rated for more than 250,000 charging cycles at 20°C ambient. (Image source: Eaton)

LIC for high-temperature operation

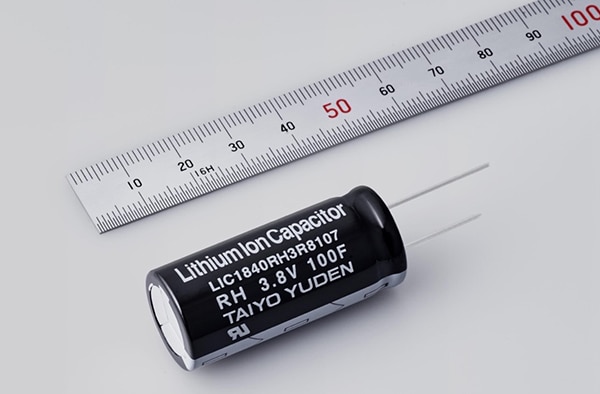

The needs of hot industrial and outdoor environments are addressed by the LIC1840RH3R8107 100 F LIC from Taiyo Yuden, which is rated for operation up to 85°C with an equivalent series resistance (ESR) of 75 milliohms (mΩ) (Figure 3). This LIC has an operating voltage range from 2.2 to 3.8 volts at 85°C, and a voltage range from 2.5 to 3.5 volts at 105°C, making it suitable for use at high temperatures. These LICs feature lower capacitance degradation rates and improved internal resistance changes when used at elevated temperatures.

Figure 3: The LIC1840RH3R8107 is a high-temperature LIC that handles 3.8 volts at up to 85°C. (Image source: Taiyo Yuden)

Figure 3: The LIC1840RH3R8107 is a high-temperature LIC that handles 3.8 volts at up to 85°C. (Image source: Taiyo Yuden)

450 F for high energy applications

If you’re designing an application that can benefit from high energy density, the 450 F TPLC-3R8/450MR18X40 from Tecate Group may be just what you need, as it’s the largest device in the company’s family of 18 LICs (Figure 4). The device is rated to deliver 2.25 amperes (A) of continuous current with a peak rating of 14.1 A. It measures 18 millimeters (mm) in diameter x 40 mm high and weighs 18 grams (g). The TPLC-3R8/450MR18X40 has a projected life of 500,000 cycles and an endurance rating of 1,000 hours when operated at its rated voltage and maximum operating temperature.

Figure 4: The 450 F TPLC-3R8/450MR18X40 (back row, center) is the largest capacity LIC in the TPLC series from Tecate Group. (Image source: Tecate Group)

Figure 4: The 450 F TPLC-3R8/450MR18X40 (back row, center) is the largest capacity LIC in the TPLC series from Tecate Group. (Image source: Tecate Group)

Designing with LICs

Like other supercapacitors, LICs have voltages that vary linearly based on their state of charge. In applications that need a stable operating voltage from a single cell, a voltage boost converter is needed. Designs using multiple LICs connected in series can often benefit from a down converter to stabilize the voltage.

Unlike other supercapacitors that can be discharged to zero volts, LICs are usually limited to 2.2 volts minimum discharge voltage to prevent damage, requiring a cell management system (CMS) for reliable operation. The CMS stops discharging the LICs at about 2.2 volts and keeps the cell voltages equalized in designs with several cells in series. While standard EDLCs typically discharge in about 30 seconds (s), LICs discharge over a few minutes; an important distinction in power quality solutions on the edge.

The lifetime of an LIC is directly related to the applied voltage and operating temperature. Higher temperatures and higher operating voltages reduce LIC lifetime. The main parameter to maximize lifetime is to lower the operating voltage, which can be accomplished by putting several cells in series.

Conclusion

LICs provide a great third option when designing distributed power quality solutions for harsh environments. Their hybrid structures combine aspects of Li-ion batteries and EDLCs in a single device. They offer long cycle lives and high energy densities, and their extended discharge over a few minutes instead of seconds can be an important distinction in power quality solutions on the edge. LICs can produce smaller, more rugged, and safer solutions. Of course, good system design practices are needed to obtain their maximum benefit.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum