Use Single-Board Computers to Create an IIoT Edge Computing Platform

Contributed By DigiKey's North American Editors

2020-04-14

Cloud-based data centers are important resources for the Industrial Internet of Things (IIoT), providing scalable mass storage, processing, analytics, regular attention to security, and continual functionality updates; but relying on the cloud for everything has several disadvantages. For example, the latency between the cloud and the edge can be too long for mission-critical functions such as process and motion control. In addition, data can be exposed to hackers and large data transfers can quickly stress communications resources. The solution to these issues is to perform as much processing and analytics as possible at the edge.

For this IIoT edge processing, computing platforms based on single-board computers (SBCs) provide designers with a growing number of cost effective and well supported solutions. Embedded systems manufacturers address this new market with 64-bit processor SBCs with high-speed memory, support for solid-state mass storage and multiple operating systems, high levels of security, dozens of pins for GPIO, and many other features.

This article will discuss the need for SBCs at the edge and their selection and integration considerations for IIoT in-house edge computing. It will then introduce by way of example SBCs from Advantech, Digi, UDOO, and VersaLogic, as well as Raspberry Pi, and show how designers can use these to create computing solutions tailored for the IIoT edge environment.

Why use SBCs for IIoT

A significant benefit of SBCs for IIoT designers is flexibility in the configuration of the overall platform, and the ability to choose only what’s required now, while offering the ability to scale—without scrapping the entire platform as might be the case with a purpose-built PC. Another advantage is that having designed the system from the ground up, designers will have gained knowledge that will be essential in the future as the need for more computing resources expands.

SBCs are as varied as the applications they’re designed to serve. Defense and aerospace systems, for example, often rely on SBCs in 3U and 6U form factors and are typically based on the Open VPX standard. Their host processors are typically high-end Intel processors and include FPGAs from the Xilinx Virtex family or graphics processing units (GPUs) as hardware accelerators, along with 12 and 16-bit analog-to-digital converters (ADCs) and digital-to-analog converters (DACs) with lots of DDR4 memory. Also, their backplanes consist of many lanes of PCIe Gen 4 and switch fabrics such as Rapid IO and PCIe. The features do come at a cost, of course.

At the other end of the scale are DIY, or “maker” SBCs that are sold in the millions throughout the world, thanks to the enormous popularity of Raspberry Pi, Arduino, and other platforms. Though much less expensive, it’s still possible to connect a group of sensors to the SBC, perform a modest level of processing, and send the result to an on-site, or edge computer based on one or more powerful SBCs. While this would obviously add to a system’s bill of materials, it might be justified because it adds intelligence to a cluster of edge sensor devices, allowing some decision making to be performed right at the edge as well as locally using edge computers.

Between defense/aerospace and DIY are SBCs designed for industrial applications that may also support Raspberry Pi and Arduino, but have vastly superior performance and rugged environmental characteristics with host processors that are members of the Arm® Cortex® family or mid-range Intel Core models. They can deliver performance equivalent to a mid-range laptop computer in a board size of less than 6 square inches (in.2), and are either supplied with DDR3 or DDR4 memory, or a memory of the designer’s choice.

Other standard features include support for SPI and SPX, Gigabit Ethernet, low-voltage differential signaling (LVDS) and PCIe, multiple types of security including a Trusted Platform Module (TPM), audio and video inputs and outputs, from 8 to 12 USB ports, as well as support for two- and four-channel SATA 3.0 storage. Typical accessories include various types of mounting hardware as well as coolers and cables. Many also accept daughter cards that include communications standards not included on the board, and in a few cases, 4G cellular. Their manufacturers also provide substantial technical resources such as development boards and prototyping kits.

The Advantech AIMB-581WG2-00A1E is a good example of an Intel-based SBC (Figure 1). The 9.6 in.2 board is powered by Intel processors up to the Xeon E3-1275 and Core i7-2600, with support for up to 32 gigabytes (Gbytes) of DDR3 memory. Another example is UDOO’s SC40-2000-0000-C0-V, a 4.72 in.2 board that is based on an AMD quad-core, 2 gigahertz (GHz) Ryzen Embedded V1605B CPU, supplemented by AMD’s eight-GPU Radeon Vega 8 graphics accelerator. It can support up to 32 Gbytes of DDR4-2400 memory and various mass storage options.

Figure 1: Advantech’s AIMB-581WG2-00A1E SBC is representative of how SBCs integrate significant functionality and expansion capability in a very small footprint. (Image source: Advantech)

Figure 1: Advantech’s AIMB-581WG2-00A1E SBC is representative of how SBCs integrate significant functionality and expansion capability in a very small footprint. (Image source: Advantech)

Unlike many other industrial SBCs, VersaLogic’s Liger VL-EPM-43SCP-08 uses the Windows operating system as well as Linux (Figure 2). It conforms to the PC/104-Plus 4.2 x 3.7 in. form factor that adds functionality by stacking boards, and unlike previous PC/104 versions, it provides support for the PCI bus as well as ISA. The VL-EPM-43SCP-08 is based on a 2.8 GHz Intel Core i7-7600U CPU supported by 8 Gbytes of DDR3 memory (expandable to 16 Gbytes) and SATA 3.0 mass storage. Other interfaces include a microSD slot, an I2C interface, selectable RS-232, RS-422 and RS-435, two mini DisplayPorts, one HDMI output, and display resolution up to 4096 x 2304. The board also meets MIL-STD-202G requirements for shock and vibration.

Figure 2: The VersaLogic VL-EPM-43SCP-08 SBC runs Windows and Linux and conforms to the PC/104-Plus form factor. (Image source: VersaLogic)

Figure 2: The VersaLogic VL-EPM-43SCP-08 SBC runs Windows and Linux and conforms to the PC/104-Plus form factor. (Image source: VersaLogic)

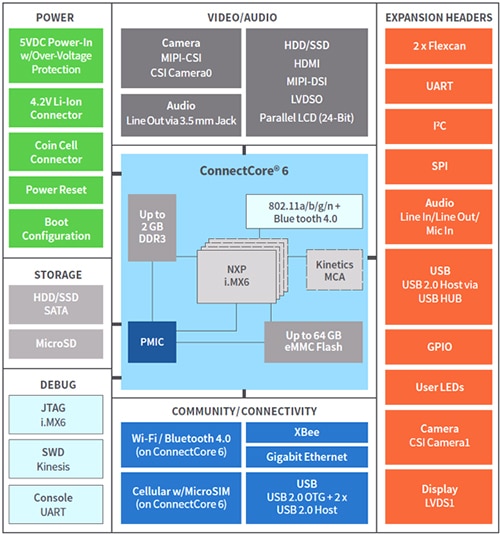

Digi takes a somewhat different approach, using its ConnectCore 6 system-on-module that is based on NXP Semiconductors’ i.MX6UL-2 processor line that integrates an applications processor with an Arm Cortex-A7 core in a single device (Figure 3).

Figure 3: The ConnectCore 6 system-in-module (SIM) integrates almost all the functionality of an SBC within a single device and is based on NXP’s iMX6UltraLite applications processor. (Image source: Digi)

Figure 3: The ConnectCore 6 system-in-module (SIM) integrates almost all the functionality of an SBC within a single device and is based on NXP’s iMX6UltraLite applications processor. (Image source: Digi)

The CC-SB-WMX-J97C version of ConnectCore 6 SIM measures 4.7 in.2, offers Bluetooth 4 and Wi-Fi, the company’s Digi XBee radio (based on the IEEE 802.15.4 standard), and optional cellular connectivity, as well as Gigabit Ethernet and support for multiple displays, a camera, and expansion connectors (Figure 4).

Figure 4: TheCC-SB-WMX-J97C SIM supports many wireless standards as well as the company’s XBee radio and measures 4.7 in.2. (Image source: Digi)

Figure 4: TheCC-SB-WMX-J97C SIM supports many wireless standards as well as the company’s XBee radio and measures 4.7 in.2. (Image source: Digi)

SBC selection considerations

For existing IIoT systems, the first step in the design process is to evaluate the company’s current needs at the edge and how much they are likely to increase in the future. The latter is more an assumption than statement of fact as it’s impossible to know precisely how fast resources will be needed. That said, the experience of most companies that have implemented IIoT shows that needs are initially understated, so the best approach is to assume that requirements will grow over time.

The next step is to determine the basic resources required, including wired and wireless connectivity, support for mass storage, and the inputs and outputs required for driving a display, audio, and video, panel lighting, a speaker, and other items. This is typically not difficult because SBCs with the performance required for IIoT will typically have all these capabilities.

Another factor to consider is a board’s ability to add functionality through expansion boards. For example, although Wi-Fi and Bluetooth transceivers are generally integrated on the board, many IIoT systems use Zigbee and possibly other short-range wireless standards, as well as low-power wide area network (LPWAN) technologies like LoRaWAN, Sigfox, or Narrowband-IoT (NB-IoT) offered by wireless carriers.

On the software side, there are many choices of operating system, most of them based either on Raspberry Pi’s official Raspbian or various versions of Linux. Arduino’s integrated development environment (IDE) supports Windows, macOS, and Linux. Windows 10 is an outlier because of its incompatibility with Raspberry Pi, and only recently has interest in this operating system been increasing for IIoT.

Finally, the environmental conditions where the system will be installed must be considered, which may require the need for a ruggedized enclosure, possibly waterproof and resistant to dirt, shock, and vibration.

Moving to SBC clusters

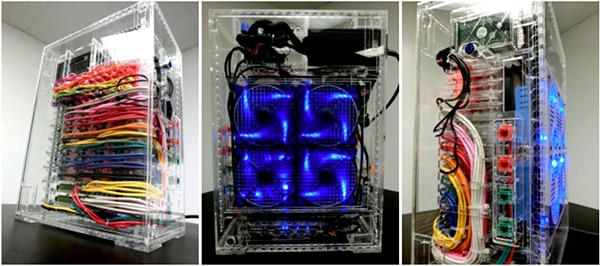

Useful as these SBCs may be, there are limits to what designers can achieve with a single board. As applications scale, however, so too can the boards. Clusters of SBCs have been built by Los Alamos National Laboratory and NASA as well as other institutions to create micro supercomputers. SBC clusters aren’t beyond the reach of IIoT designers either, as demonstrated by a 40 node Raspberry Pi 3 Model Bs cluster (Figure 5). This 40 node cluster is based on 40 Raspberry Pi 3 Model Bs, has 20 Gbytes of memory, can support up to 12 terabytes (Tbytes) of mass storage, yet measures only 9.9 x 15.5 x 21.8 in.

Figure 5: This 40 node cluster based on 40 Raspberry Pi 3 Model Bs has 20 Gbytes of memory, can support up to 12 Tbytes of mass storage, yet measures only 9.9 x 15.5 x 21.8 in. (Image source: LikeMagicAppears!)

Figure 5: This 40 node cluster based on 40 Raspberry Pi 3 Model Bs has 20 Gbytes of memory, can support up to 12 Tbytes of mass storage, yet measures only 9.9 x 15.5 x 21.8 in. (Image source: LikeMagicAppears!)

Systems like these should grab the attention of embedded systems developers, demonstrating how they can build upon Raspberry Pi as well as other architectures to create powerful, scalable, SBC clusters for IIoT edge computing. For this application, the Raspberry Pi Model 3B+ is a good starting point. Compared to traditional clusters, SBC clusters are much smaller, low-cost, and consume modest amounts of power, making them well suited for the confines of the edge.

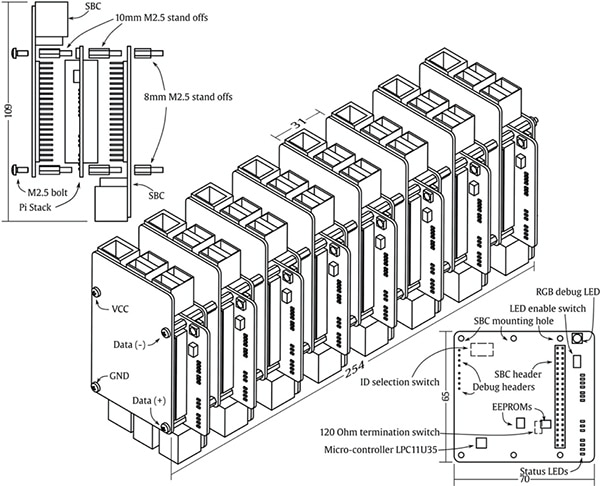

A variety of approaches have been demonstrated to achieve very high performance in a confined space. For example, the Pi Stack technique introduces DC power into the cluster from a single point, with power distributed throughout the cluster (Figure 6). This reduces cabling and allows more Raspberry Pi boards to fit into a given footprint. Communications between the nodes is achieved using the Ethernet interfaces provided by the SBC.

Figure 6: An SBC cluster built using the Pi Stack construction approach presented by Philip Basford et al. (Image source: Future Generation Computer Systems)

Figure 6: An SBC cluster built using the Pi Stack construction approach presented by Philip Basford et al. (Image source: Future Generation Computer Systems)

What’s perhaps most remarkable about SBC clusters is their ability to deliver extremely high performance using low-cost, off-the-shelf SBCs along with power supplies and assorted peripherals. For edge computing for the IIoT, this concept is relatively new, but worth serious consideration.

Conclusion

The increasing number of SBCs designed for IIoT applications provide very appealing solutions for designers tasked with building an edge computing platform. When combined with a power supply, enclosure, and some peripherals, they can be tailored and scaled cost-effectively to meet the needs of a wide variety of operating environments in a very small footprint.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.